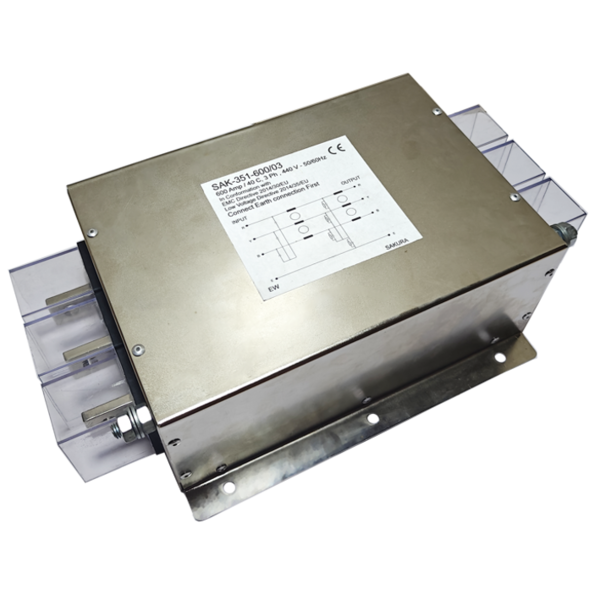

General Purpose Power Line Filter In Deep Drawn Metal Box: Enhancing Electrical Performance and Safety

In today’s fast-paced technological landscape, the demand for efficient power management and electrical safety is paramount. One crucial component that plays a significant role in achieving these goals is the general purpose power line filter in a deep drawn metal box. In this article, we will explore the importance of this innovative solution and how it enhances electrical performance while ensuring safety.

What is a General Purpose Power Line Filter?

A general purpose power line filter is an electronic device designed to reduce electromagnetic interference (EMI) and radio frequency interference (RFI) from power lines. It acts as a protective shield for electrical circuits, preventing unwanted noise from affecting sensitive electronic equipment. These filters are widely used in various industries, including telecommunications, medical devices, industrial automation, and consumer electronics.

The Role of Deep Drawn Metal Box

The deep drawn metal box serves as the ideal housing for a general purpose power line filter. This type of enclosure is formed by drawing a flat sheet of metal into a three-dimensional shape using a deep drawing process. The resulting box offers numerous advantages for housing sensitive electronic components.

First and foremost, deep drawn metal boxes provide excellent shielding capabilities. The metal construction effectively contains the electromagnetic emissions generated by the power line filter, preventing them from interfering with nearby electronic devices. This feature ensures a clean and reliable power supply, minimizing disruptions and maintaining the integrity of sensitive equipment.

Furthermore, the durability and robustness of deep drawn metal boxes make them suitable for various environments. The rigid structure protects the internal components from physical damage, moisture, dust, and other external factors that may compromise the performance and longevity of the power line filter. This added level of protection ensures the filter operates optimally even in harsh conditions.

Benefits of General Purpose Power Line Filter in a Deep Drawn Metal Box

Enhanced Electrical Performance: By incorporating a general purpose power line filter within a deep drawn metal box, electrical performance is greatly improved. The filter eliminates unwanted noise and interference, resulting in cleaner power delivery to connected devices. This enhances the overall efficiency and reliability of the electrical system, reducing the risk of malfunctions or equipment failures.

Increased Safety: Electrical safety is a top priority in any application. The combination of a power line filter and deep drawn metal box adds an extra layer of protection against electrical hazards. The metal enclosure provides grounding and insulation, minimizing the risk of electrical shock and preventing the escape of any potential electrical arcs or sparks. This ensures a safe operating environment for both equipment and personnel.

Compact and Space-saving Design: Deep drawn metal boxes offer a compact and space-saving design, making them ideal for applications with limited space availability. The efficient use of space allows for easy integration of the power line filter into existing systems without compromising functionality or performance.

Cost-effective Solution: Combining a general purpose power line filter with a deep drawn metal box offers a cost-effective solution. The durability and longevity of the metal enclosure reduce the need for frequent replacements or repairs, resulting in long-term cost savings. Additionally, the enhanced electrical performance and safety features of the filter contribute to minimizing downtime and maintenance expenses.

In conclusion, the general purpose power line filter in a deep drawn metal box is a vital component in achieving optimal electrical performance and safety. Its ability to reduce EMI and RFI, combined with the shielding and durability of the metal enclosure, ensures a reliable power supply while protecting sensitive equipment from external factors. By investing in this innovative solution, businesses can enhance their electrical systems’ efficiency, prolong equipment lifespan, and create a safe operating environment.