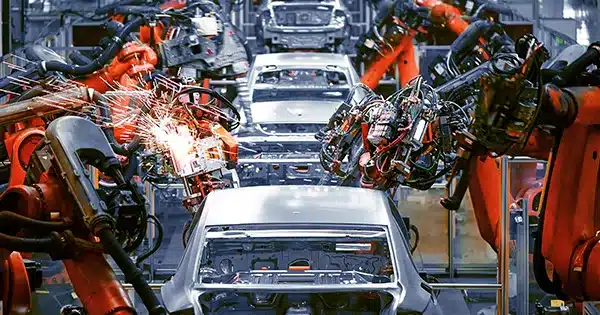

In today’s high-tech manufacturing environment, where precision, speed, and reliability are critical, electromagnetic interference (EMI) can pose a serious threat to operational efficiency. From automated machinery to control systems and robotics, EMI can disrupt signals, damage equipment, and lead to costly downtime. This makes EMI filters an essential component in every modern manufacturing facility.

At Sakura India, we provide a comprehensive range of EMI/RFI filters specifically designed to meet the demanding needs of the manufacturing sector. Explore our offerings at our Products Page.

The Role of EMI Filters in Modern Manufacturing

1. Reducing Electromagnetic Noise from Machines

Machines like CNCs, injection molding equipment, and welding systems generate high-frequency noise during operation. EMI filters reduce this interference, preventing it from affecting nearby equipment or the power grid.

2. Protecting Sensitive Automation & Control Systems

Manufacturing plants rely heavily on Programmable Logic Controllers (PLCs), Human Machine Interfaces (HMIs), and Industrial PCs. EMI filters ensure these systems operate reliably without being disrupted by surrounding noise.

3. Improving Signal Integrity in Communication Networks

Modern factories use Industrial Ethernet, wireless controls, and sensor networks. EMI filters help maintain clean data transmission and avoid system errors caused by interference.

4. Enhancing Safety and Equipment Lifespan

By shielding electronics from harmful EMI, filters reduce the risk of overheating, malfunction, or failure, ensuring safer and longer-lasting machinery performance.

5. Meeting EMC Compliance Requirements

Compliance with EMC standards such as IEC, CISPR, and EN is essential in industrial environments. EMI filters from Sakura India help manufacturers meet these regulations with confidence.

Recommended EMI Filters from Sakura India for Manufacturing

Three-Phase EMI Filters

- Ideal for large industrial machines, power distribution panels, and variable frequency drives (VFDs).

Single-Phase EMI Filters

- Suitable for smaller equipment, automated assembly lines, and control panels.

DC EMI Filters

- Perfect for DC motor drives, power supplies, and battery-powered equipment.

Why Manufacturers Trust Sakura India

- Robust Construction: Designed for continuous use in high-vibration and high-temperature environments.

- Customizable Solutions: Tailored to meet specific current, voltage, and footprint requirements.

- High Attenuation Levels: Efficient filtering of both common-mode and differential-mode noise.

- Field-Proven Reliability: Trusted by top manufacturers across sectors like automotive, electronics, packaging, and more.

Conclusion

EMI filters are a critical part of ensuring uninterrupted production, protecting sensitive equipment, and maintaining regulatory compliance in manufacturing environments. With high-performance filtering solutions from Sakura India, manufacturers can minimize downtime and maximize productivity.

To learn more, visit our full EMI Filter Product Range or contact our team for a tailored solution to your industrial needs.